Annex K3: Difference between revisions

No edit summary |

No edit summary |

||

| Line 31: | Line 31: | ||

== Specifications == | == Specifications == | ||

Model: [https://github.com/Annex-Engineering/Gasherbrum-K3/tree/R1 Annex K3 1.0] | Model: [https://github.com/Annex-Engineering/Gasherbrum-K3/tree/R1 Annex K3 1.0], Sherpa Mini extruder w/Bondtech parts. All printed bits are in ASA+CF, most screws are on Loctite (please put loctite back on if you're replacing them, it can and did vibrate apart without) | ||

Controls: Klipper on RPi4, BTT Octopus Pro controller, 48V Trinamic stepper drivers | Controls: Klipper on RPi4, BTT Octopus Pro controller, 48V Trinamic stepper drivers | ||

Latest revision as of 02:52, 27 November 2024

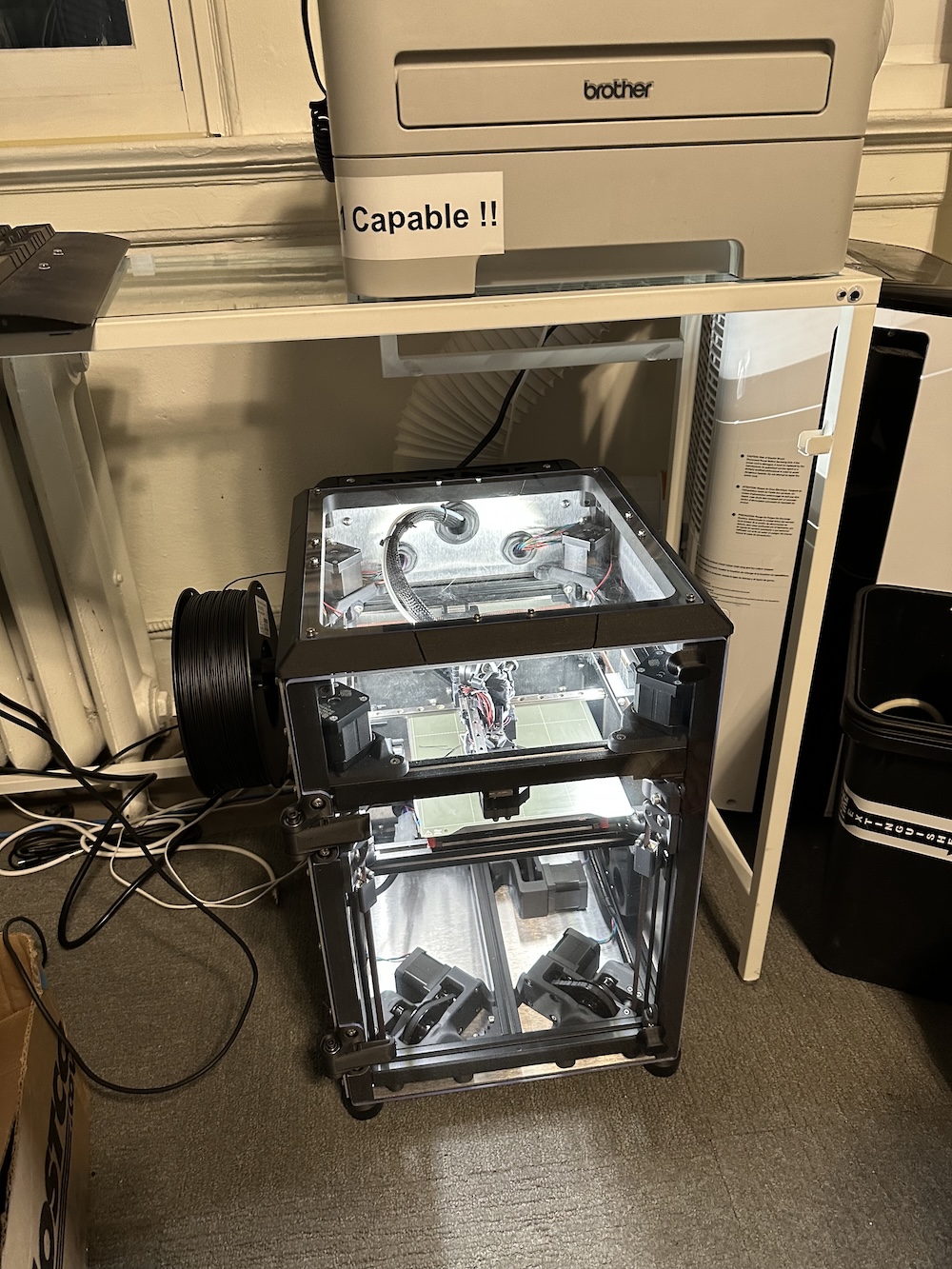

A fast 3D printer for high temperature materials (ASA, ABS, Nylon etc).

How to print

Power up the printer with the switch on the back, give it a couple minutes to boot; there should be a web UI at http://annex.local.

Before printing

Make sure the print bed is clean and there is a magnetic sheet on it. Do not let the mag sheet stick over the left edge and catch the purge bucket.

Hit "Home all" after turning it on; it should home X and Y, pick up the probe, boop the middle of the print bed and put it back.

If the bed has been messed with, also press "square bed to machine" for 3-point leveling; not needed for routine printing.

Turn on the filter fan ("Rebreather" to 100%) for better airflow in the chamber and more even heating.

Preheat the bed; use the Preheat function in right click menu for ASA/ABS or just type in desired temps. If you're not in a hurry, letting it sit for a half hour once at temperature levels out to minimize warping.

Slicing

Currently the only slicer we have configs for is SuperSlicer; the config bundle is here: [1]

I recommend using "K3 volumetric ABS+" (with or without extrusion override) but do not be afraid to experiment with your own. These presets are NOT necessarily good. There are some spare parts in the box, and if you really break something, tell @vlad please.

Slice your model, export and upload to the Klipper UI (presets linked below but need tuning as of right now).

Choose your g-code, hit print and enjoy the show. It's fast and fun to watch.

After printing

Let it sit for 30 minutes or so with the door closed and rebreather going to absorb fumes in the chamber and avoid a whiff of ABS nastiness when you open the door. Open the door and let the heatbed cool off, ideally the print should just pop off the bed on its own. If you are in a hurry, carefully remove the mag sheet from the bed (it's very hot!) and let it sit outside to cool faster. Do not try to pry the part off of a hot sheet, it'll stick and make a mess.

Specifications

Model: Annex K3 1.0, Sherpa Mini extruder w/Bondtech parts. All printed bits are in ASA+CF, most screws are on Loctite (please put loctite back on if you're replacing them, it can and did vibrate apart without)

Controls: Klipper on RPi4, BTT Octopus Pro controller, 48V Trinamic stepper drivers

Hotend: Slice Mosquito Magnum, 50W heater, 500C max but not tested above 300C.

Nozzle: Bondtech CHT 0.4mm as of now (no abrasive materials with this nozzle please!)

Bed probe: microswitch on magnets (Annex Quickdraw)

Heated bed: 170x170mm MIC-6 aluminum plate, magnetically attached Prusa Mini steel sheets, Fabreeko 300W AC heater, 150C safety cutoff but please be careful going over 100C and do not leave the printer unattended.

Air filter: yes, Annex Rebreather with carbon grains (only use acid-free carbon, there is a bag in the parts box or it instantly rust!)

Filament Runout sensor: installed but not configured (volunteers welcome!)

Current status

Works, has ABS+ filament (very smelly), may need tuning and NEEDS ASA filament

Projects and upgrades

First of all I recommend getting some ASA filament (Polymaker brand is pretty good) - it's far less noxiuos than ABS, UV-resistant, warps less and is generally a much nicer material to print. BUT I do not have a ready to go slicer profile for ASA.

There are parts for some useful upgrades in the "Annex parts" box:

- 50W heater: should enable higher flow rates and hopefully faster printing in ASA. Right now you can see the temperature drop at high flow rates (30+mm^3/s) as the PID tries to catch up. Could be done on its own or combined with other extruder upgrades.

- Extruder rebuild: there is a Beacon RevH sensor in the small white mailing box, which should enable ultra fast bed leveling and input shaper tuning without nozzle swaps. Unfortunately, the entire extruder needs to be rebuilt for that. The new plastic parts printed in ASA+CF are already there; it may not have some of the metal bits (axles, heat-set inserts) - they could be scavenged from the old one but it's probably best to just order them. There's also a cable routing board ("k3rabiner") and a harness for it to make it all modular and easily detachable. Note that the new extruder is a mirror image of the original, that's intentional.

- Filament sensor: should be a simple change in Klipper configs