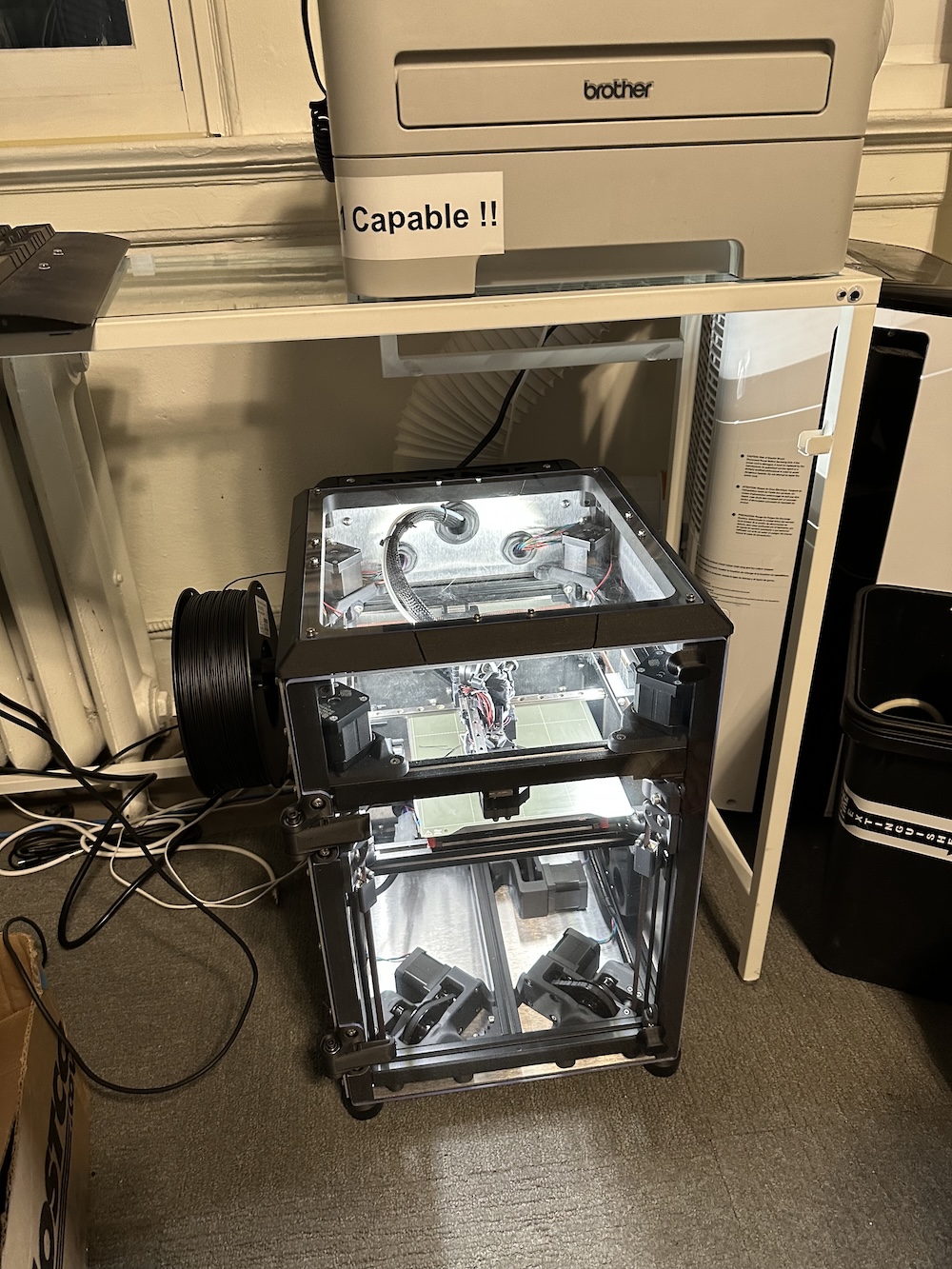

Annex K3

A fast, enclosed 3D printer for high temperature materials (ASA, ABS, Nylon etc).

Current status

Fully operational! The first layer Z height is set a bit low but I haven't found a way to adjust it independently of Beacon probe calibration.

The recommended material is Polymaker ASA.

How to print

Power up the printer with the switch on the back, give it a couple minutes to boot; there should be a web UI at http://annex.local. (https will not work)

Before printing

Read the 3D Printing Commandments

Make sure the print bed is clean and there is a magnetic sheet on it. Do not let the mag sheet stick over the left edge and catch the purge bucket.

Hit "Home all" after turning it on.

If the bed has been messed with, also press "square bed to machine" for 3-point leveling; not needed for routine printing.

Turn on the filter fan ("Rebreather" to 100%) for better airflow in the chamber and more even heating.

Preheat and level the bed: hit PRE_PRINT_PREP; once the bed reaches print temperatures it'll be 3-point leveled and then mesh leveled with the contactless Beacon probe. Once the printer stops moving, you're ready to print.

Slicing

Currently the only slicer we have configs for is SuperSlicer; the config bundle is here: [1]

I recommend using "K3 volumetric ASA" in Print settings, the "K3 ASA" filament profile and "K3 mine" printer configuration. Do not be afraid to experiment with your own. These presets are NOT necessarily good. There are some spare parts in the box, and if you really break something, tell @vlad please.

Slice your model, export and upload to the Klipper UI.

Choose your g-code, hit print and enjoy the show. It's fast and fun to watch.

After printing

Let it sit for 30 minutes or so with the door closed and rebreather going to absorb fumes in the chamber and avoid a whiff of plastic nastiness when you open the door. Open the door and let the heatbed cool off, ideally the print should just pop off the bed on its own. If you are in a hurry, carefully remove the mag sheet from the bed (it's very hot!) and let it sit outside to cool faster. Do not try to pry the part off of a hot sheet, it'll stick and make a mess. Please clean up the printer after you're done.

Specifications

Model: Annex K3 1.0, Sherpa Micro extruder w/Bondtech parts. All printed bits are in ASA+CF, most screws are on Loctite (please put loctite back on if you're replacing them, it can and did vibrate apart without)

Controls: Klipper on RPi4, BTT Octopus Pro controller, 48V Trinamic stepper drivers

Hotend: Slice Mosquito Magnum, 50W heater, 500C max but not tested above 300C.

Nozzle: Bondtech CHT 0.4mm as of now (no abrasive materials with this nozzle please!)

Bed probe: Beacon RevH contactless inductive probe + accelerometer.

Heated bed: 170x170mm MIC-6 aluminum plate, magnetically attached Prusa Mini steel sheets, Fabreeko 300W AC heater, 150C safety cutoff but please be careful going over 100C and do not leave the printer unattended.

Air filter: yes, Annex Rebreather with carbon grains (only use acid-free carbon, there is a bag in the parts box or it instantly rust!)

Filament Runout sensor: installed but not configured (volunteers welcome!)

Projects and upgrades

Filament sensor software support

There's a filament runout/jam sensor installed but it is not currently set up in Klipper. Hooking it up correctly should be an easy project.

Print head rebuild

Completed, please enjoy the new contactless bed probe!

Metal motor brackets

There is a set of waterjet-cut steel XY motor mounts in the parts box. These mounts are the main load bearing parts in the printer, and replacing printed pieces with steel should enable even higher speeds or better quality at the same speed. Unfortunately, replacing the corners involves pretty major disassembly of the printer so they have not been installed.